What we do

By our advanced machining equipment, we are able to offer CNC machining services like CNC milling, turning, mill turn, 5 axis CNC machining, die casting, also we provide one stop service for plastic/rubber industries.

CNC turning Machining

Machining by CNC turning (lathing) machines, and automatic lathing machinesApplication

CNC turning is a manufacturing process for getting desired shape parts with bars of material held in a chuck and rotated while a tool is fed to the piece to remove material.

CNC milling Machining

3 axis, 4 axis CNC milling machining center, Manual milling machinesApplication

For any parts with non-circular irregular sections, material including steel, aluminum, copper, zinc, titanium, plastic and some other alloys.

Multi-axis CNC machining

Machining by CNC mill turn, swiss type automatic CNC lathe turning machines, 5 axis CNC machinesApplication

5 axis or some other multiple axis CNC machines are used for machining complex / curved surface parts, or parts which need high precision or short production time by reducing number of champing times.

Die casting

Tonage of die casting machines range from 90T to 800T, able to produce die casted parts up to 16kgApplication

Die casting process is for producing complex-shaped aluminum alloy, zinc alloy or magnesium-aluminum alloy components / parts, has features of high production of efficiency and low costs.

One stop Services

Wire EDM, sheet matla fabrication, tooling building, injection molding.Details

Heat treatment is for parts have hardness requirement to achieve high abrasive resistance, or impact resistant / toughness ability, others are for parts which required good surface /appearance.

Featured Cases

All below the cases are displayed after we get agreements or authorizations from our customers, no confidential product or part displaying.

722M24 motorcycle transmission input shaft OEM spur gear shaft custom manufacturing

Material: Alloy steel 722M24 Rough overall dimension: Φ50*200mm; Machining process: CNC turning+hobbing; Precision up to: 0.005mm;

SUS 316L 1.4404 stainless steel semicircle head turn milled parts

Material: 316L Stainless steel; Rough overall dimension: Φ30(max)*60mm; Machining process: CNC lathe

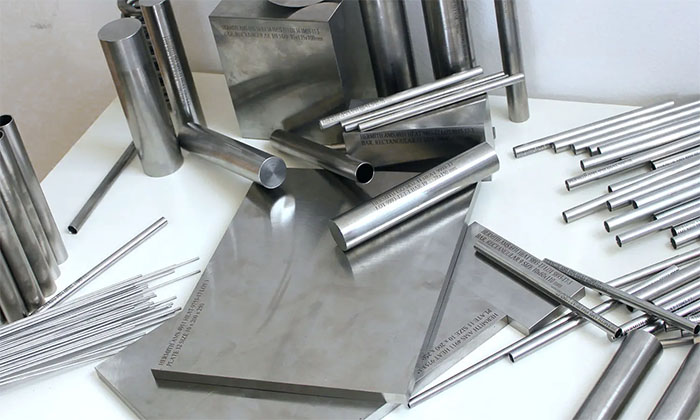

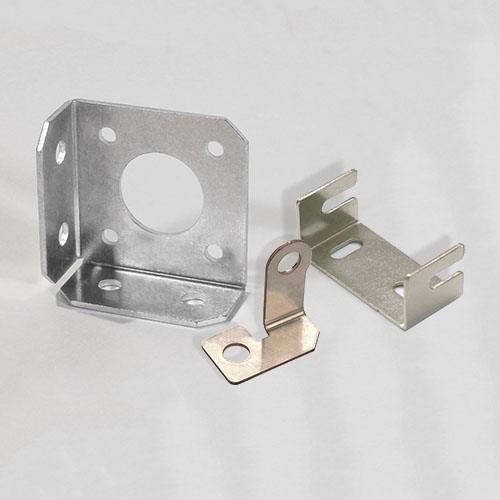

Stainless steel Aluminum parts sheet metal fabrication

Material: Steel/Stainless steel /Al sheet metal Size: OEM Machining process: Punching/Bending/Laser cutting/CNC

Non standard Torx bolt unstandard screw manufacturing China

Material: Stainless steel, carbon steel or OEM Specification: Customized

Stainless steel Pipe clamp hose fastening part

Material: Stainless steel Size: customized Manufacturing process: sheet metal fabrication

British or Metric Titanium alloy lock Bulkhead hex nut custom Manufacturing

Material: Titanium alloy / Stainless steel Dimension: Customized Thread: British, metric or non

304 stainless steel swiss type CNC machining medical equipment parts

Material: AISI304; Overall Size: 30*30*45mm; Tolerance: up to ±0.005mm Manufacturing process: Swiss

Our Value & Advantages

Latest News

Specifications and Applications of Titanium alloy

Titanium is one of the elements with high abundance in the crust, ranks ninth with 0.64% proved content in the crust. Titanium has low density, high specific strength and corrosion resistance. Titanium and titanium

Tolerances of Drawing Effect on Cost of CNC machining China

During the years of cooperation with many customers in area of CNC machining, we'v found that some customers are very professional in the question of, how tolerances effect cost of CNC machining, but there

The difference between 3 axis 4 axis 5 axis CNC machining

CNC milling involves removing materialby rotary tools.One is the workpiece keeps still and the tool moves to the workpiece, another one is the workpiece enters the machine at a predetermined angle.The more moving shafts