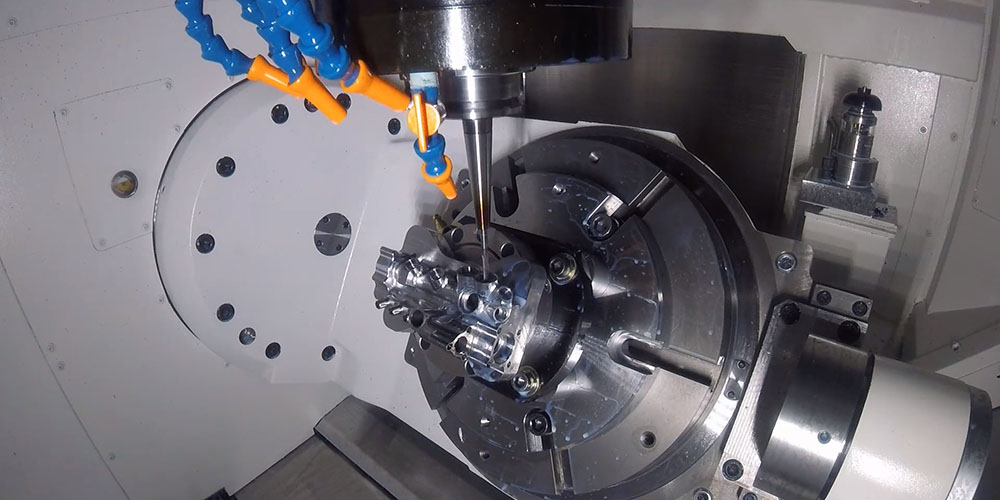

5-axis machining process is usually used to achieve complex surface machining. The 3+2-axis machining offers a 3-axis milling process, with two additional axes to rotate the hold tool in a fixed position as opposed to manipulating it repetitively during the machining process. A 5-axis machine helps you work on tighter tolerances to achieve complex geometries while a 3+2 system allows you to hold your less complex parts in positions that allow better access to the features.

- Shorter clamping time of workpieces, shorter machining time compared with multiple clamping&machining on 3 axis CNC machines.

- Stronger capability for machining complex designed parts.

- Higher precision, especially repositioning accuracy.

High precision, highly difficult complex parts, parts with complex curved surfaces etc.